- #Cnc Design Program Mac And Windows#

- #Cnc Design Program Update In 2009#

- #Cnc Design Program How To Engrave A#

Same goes (double) for drawers. CNC will be useful for many other things too.While not strictly a CAD package, Inkscape is very popular for 2D designs for CNC machining. Its generally used more for artistic projects than precise.I can stumble my way through building cad files to cut these parts but I’m curious if there’s some software out there that (affordably) can turn a cabinet design into cut/g-code files? I think the cost would have to be less than $1k for it to make sense for the home/diy guy but I’m open to +\-. In your design software list from your previous post, I didnt find mention of Inkscape (primarily an illustration software) but it also can create SVGs that can be used to do 2D CNC designs.

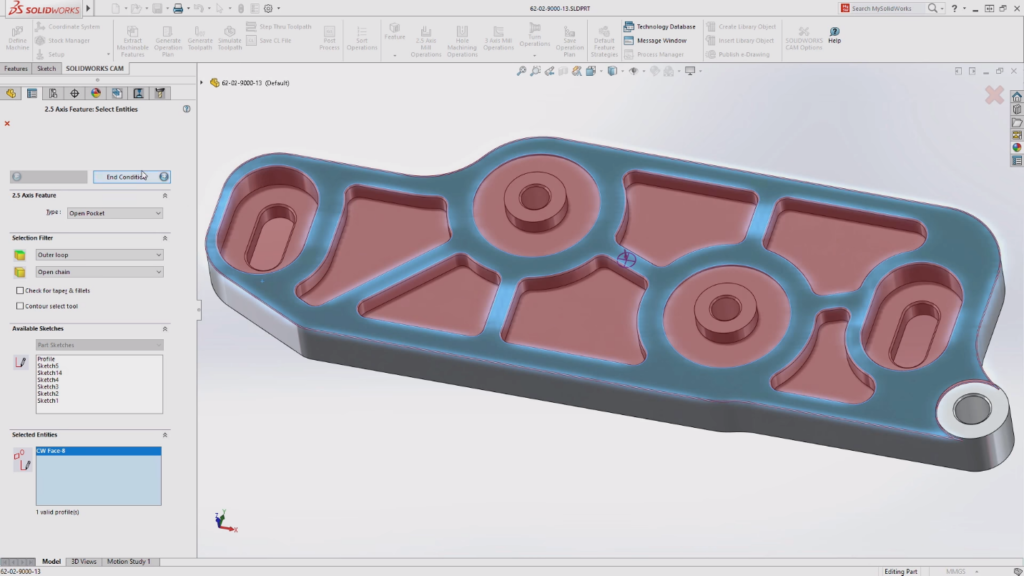

My current tool of choice is a CNC router. Excellent results can come from a small CNC router, but don’t forget the software!CNC tools, whatever their flavor, can greatly enhance your “making” or DIY ability. This package has a portfolio of highly advanced features for 3D design and modeling, simulation, generative design, data management, and collaboration. Combined with its manufacturing features, these make Fusion 360 one of the best CAD software for CNC machining.What I want to do - today I’m comfortable with my cabinet building processes but I’m growing tired of switching operations.

Cnc Design Program Mac And Windows

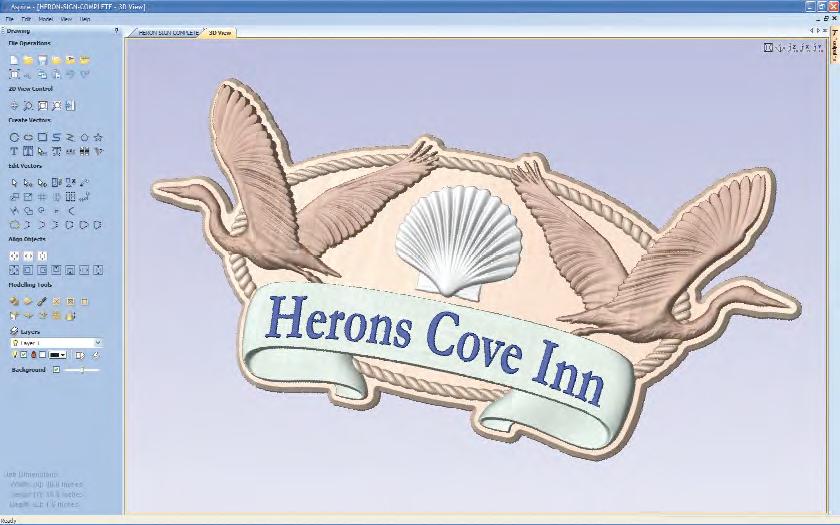

Perhaps I’ve been spoiled or brainwashed by quite a few years of working with Pro/E, and Solidworks to a much smaller extent, because I found Sketchup frustrating. I’m very familiar with AutoCAD, and it’s available for Linux, Mac and Windows.If you want to get into 3D design, Sketchup seems to be more-or less the standard for casual makers/hackers/etc. If you want to do something more dimensionally-driven, my preferred tool is Draftsight. Inkscape is a really cool program for generating more artistic pieces, like this random tree that I cut a while ago. To generate my part drawings, I’ve experimented with Inkscape, a vector graphics editor, and Draftsight, which is more or less free AutoCAD.

I’ve tried out several packages, and all have their advantages and disadvantages: For most circumstances, however, G-Code is much easier to produce using a CAM program to translate your CAD model into this format. You can write G-Code by hand, and for very simple circles or lines, this might be practical. Generate Gcode Meshcam screen per my reviewG-Code, unlike what some mid 90’s rappers would have you believe, stands for General Code, and is what directly controls a CNC machine.

I primarily use this CAM program. CAMBam – Reasonably priced at $149, with a very good free trial period. More of a 2D environment, and you can draw your parts on this program if you like. ESTLCam – Inexpensive at $35, and it has a good-looking interface. Somewhat limited in capability, and the documentation may take a little time to figure out.

Custom CAM routine – If you’re a programmer (or pretend to be), it’s possible that you could write your own Gcode generating script. It’s geared more toward 3D users, so it wasn’t a great fit for my Draftsight-centric CAD style. Along with this polish, it is more expensive than some at $250.

Cnc Design Program How To Engrave A

The first is me engraving a Tiger Paw, whereas the second video is a tutorial I did on how to engrave a logo using Inkscape. If you have worked extensively with LinuxCNC please share you experiences by leaving a comment below.To wrap things up, here’s two CNC videos that I’ve made. As I use Ubuntu quite a bit now, I might take a different track today. The challenge of leaning a new OS along with a new router seemed like too steep of a learning curve, so I haven’t tried this option. When I started leaning CNC, I was almost entirely unfamiliar with Linux.

It has both 2D and 3D options for either engraving or full 3D cutting.Mach3 is ok, but my PC crashes every once in a while, even after eliminating most of the causes.My CNC machines are modified Sieg (3D) and Enco (2D) knee mills. I bought a used version from eBay and it works fine. It’s tricky to learn, but does the job for both CAD and CAM. Yes, there is a learning curve, but half the fun is learning, so I enjoy, rather than despise this part.My CAD/CAM solution is BobCAD. When he’s not at work or in the garage, you can find him on Twitter his projects blog JCoPro.net, or on his photography-related blog DIYTripods.com.Posted in cnc hacks, Featured, Tool Hacks Tagged cam, CamBam, cnc, inkscape, mach3, router Post navigationI am a hobby CNC explorer. Additionally, Jeremy is an avid maker and former Hackaday staff writer.

Cnc Design Program Update In 2009

Through version 2.0 it was installed in Host Protected Area though it could also be installed in a normal hidden partition on non-original equipment hard drives. XP Embedded is still very commonly used, though Microsoft did an update in 2009 which was still pretty much XP based before they released the next version which is (IIRC) Windows 7 based.AFAIK, the only time Windows embedded has been used on a consumer PC was Dell Media Direct (through version 3.5) on some of their laptops. Same code-base as ordinary Windows for desktops and laptops but has a system that does extreme customization of the install so it has only the components absolutely required for the system it will be used on. Tackling on the CAD, CAM, integration, PC, CNC building all at once can be daunting.This hobby can be handy: I just carved out of aluminum some quadcopter legs that are no longer made.Might be running an embedded version of Windows.

Mustek was one of the first companies to prove it when they released Windows 2000 (and later XP) drivers for most of the parallel port scanners they’d made, including many discontinued models.Meanwhile, UMAX dropped support for all their parallel port scanners, claiming it was “impossible” to use a parallel port for scanning in Windows 2000 and XP. Contrary to popular belief, it is possible to do anything with the parallel port that was possible with Windows 9x or DOS. After 3.5, Dell abandoned the special partition and Windows Embedded, making Media Direct simply a multimedia program running in normal Windows.Windows Embedded allowed for a faster loading version of Windows and the ability to run normal Windows multimedia software, unlike the similar scheme used by Hewlett Packard that ran a custom build of Linux for their fast booting CD and DVD playing mode.On a CNC machine it would be possible to create a special install of Windows embedded that has no extra baggage, and has special drivers for realtime control of machine control hardware.Mach 3 has its own parallel port driver, which I assume does some tricks like that.

Personally I don’t use it. You can build the RTAI kernel extensions on a very up to date kernel version and run that with the LinuxCNC code.Admittedly the LinuxCNC ISO image is pretty stale today. Being such there is no single cut and dried, here you go, this is the latest code you can have answer really.

0 kommentar(er)

0 kommentar(er)